Case study

Škoda Auto relies on Atrea TPV ventilation ceilings

The largest industrial kitchen in the Czech Republic,

located at the Škoda Auto headquarters.

located at the Škoda Auto headquarters.

Feedback from the customer

“ATREA solution meets all our requirements for functionality, design, and quality, with provisions for regular servicing to ensure long-term system reliability and performance.”

The result

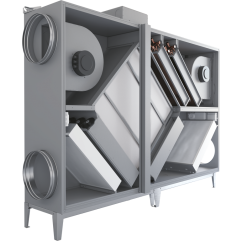

Compactness

Compact dimensions with an emphasis on depth and smart solutions for limited installation spaces.

Constant temperature

Constant temperature maintained between 18 and 20 °C.

High efficiency

High efficient heat recovery cores developed and produced by ATREA and energy saving top class fans.

RD5 control system

The high-tech control system developed and manufactured in house is tailored to our air handling units and used throughout the whole portfolio.