Blog

Published:

Grease Filters for Professional Kitchens: Safe, Efficient and Hygienically Clean Environment

In professional kitchens, the air contains more than just heat and steam. Grease aerosols, oil and moisture put a heavy load on both the kitchen and the entire ventilation system. Effective air filtration is therefore essential for hygiene, safety and the long life of the system. Modern grease filters are no longer just metal meshes — they are advanced technologies that improve air quality, reduce maintenance costs and enhance operational safety.

Why Air Filtration in Kitchens Matters

Every kitchen produces a mixture of grease vapours, aerosols and moisture. Without sufficient filtration, these particles accumulate in the ductwork, reduce exhaust efficiency and pose a significant fire risk. Poorly maintained filters also worsen air quality and make the operation more expensive — clogged fans consume more energy and require more frequent servicing.

A well-designed filtration system provides several essential functions:

- ensures a hygienic and safe working environment,

- protects ventilation components from clogging,

- reduces the risk of grease fires,

- extends system life and cleaning intervals.

Types of Grease Filters Used in Commercial Kitchens

Professional kitchen ventilation uses multi-stage filtration. Basic grease filters capture larger particles, while fine and cyclone filters remove even microscopic aerosols.

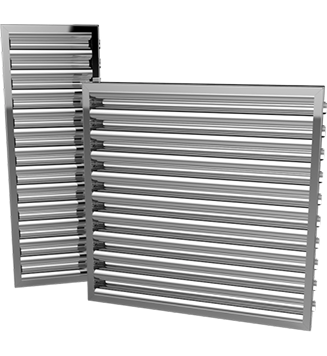

Lamella Filters

Lamella separators are made of stainless steel and work on the principle of changing the airflow direction. Grease particles are trapped on the lamella surfaces, where they condense and drain into collection trays. They are easy to wash and suitable for most professional kitchens.

Cyclone Filters

Cyclone separators belong among the most efficient industrial air filters — they can capture up to 95% of grease particles. The air inside rotates at high speed, separating grease by centrifugal force and collecting it at the bottom. Cyclone filters are ideal for heavy-duty or continuous operation, such as hotel or production kitchens.

Standards and Safety

Air filtration in commercial kitchens must comply with strict European standards — particularly VDI 2052 and EN 16282. These standards define requirements for filtration efficiency, hygiene, materials and safety parameters. Manufacturers of professional ventilation systems must test their products in accredited laboratories to verify or exceed the prescribed limits. This ensures high performance, safety and long-term reliability.

Advantages of Modern Kitchen Air Filtration

Effective filtration brings numerous operational and long-term benefits:

- captures up to 95% of grease aerosols, protecting ducts from clogging,

- reduces service costs and extends the lifespan of fans and air handling units,

- maintains stable ventilation performance and hygienic air quality,

- eliminates odours and improves air comfort in kitchens and surrounding areas.

In practice, lamella and cyclone filters have proven to be the most effective solutions — combining high efficiency with easy maintenance. For large-scale operations, the ideal solution is the TPV ventilation ceiling with multi-stage filtration and optional UV-C disinfection, or integration with DUPLEX heat recovery units for maximum energy savings.

ATREA provides complete ventilation and filtration systems for professional kitchens — from system design to final installation — with a focus on long-term performance, hygiene and operator comfort.

Contact Us

Do you need help designing or upgrading your kitchen filtration system? We’ll help you choose the optimal solution tailored to your operation type, kitchen size and hygiene standards.

Get in touch — we’ll make sure your kitchen breathes clean and safe air.

Written by:

Jan Foret, Commercial Kitchen Ventilation Expert

Contact us

Tell us how we can help

Do you have questions, need advice, or want more information about our products and services? Let us know through this contact form. Our team will respond as soon as possible with a solution customized just for you.